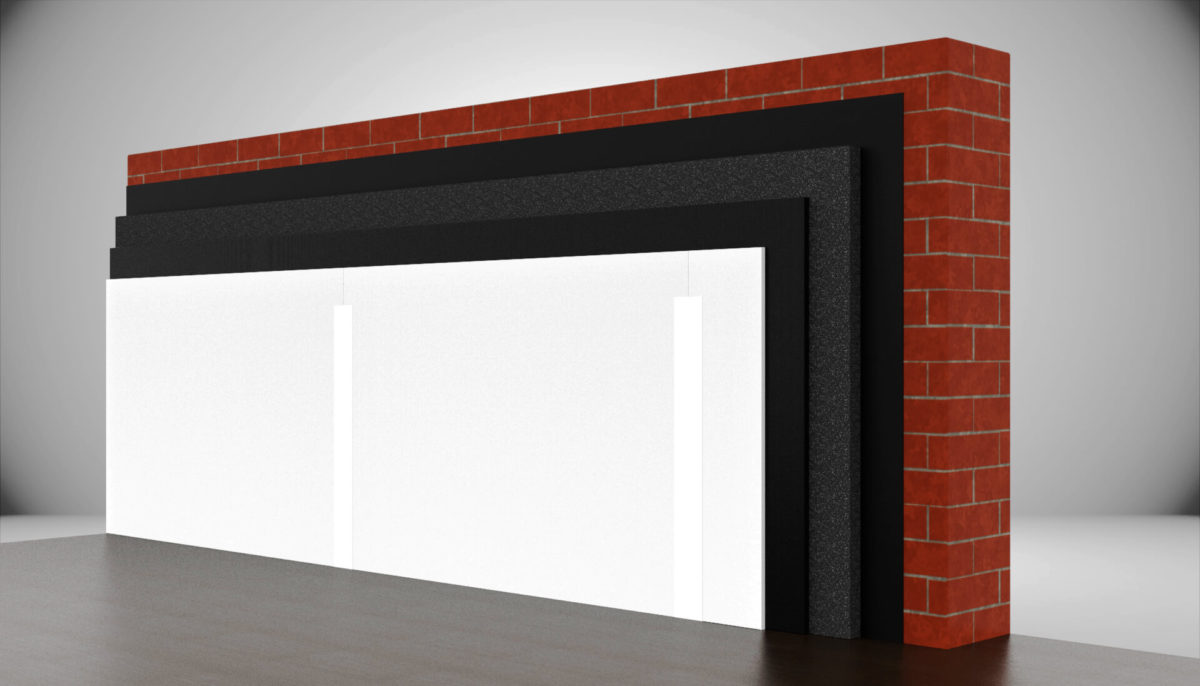

BASIC SYSTEM DATA

| System thickness: | 74mm |

| Number of layers: | 4 |

| Acoustic insulation: | 47,1dB |

| Weight: | 24kg/m2 |

ACTIVE SYSTEM COMPONENTS

| Component | Thickness | Density |

|---|---|---|

| Closed-cell solid rubber | 2mm | 2000kg/m3 |

| Semi-open cel rebound polyurethane foam | 40mm | 160kg/m3 |

| Closed-cell rubber foam | 19mm | 60kg/m3 |

| Acoustic plasterboard | 12,5mm | 1020kg/m3 |

EFFICIENCY: Rw 47dB

DOWNLOAD:

USED MATERIALS

| 1. Solid rubber |

| 2. Rebound polyurethane foam |

| 3. Rubber foam |

| 4. Acoustic plasterboard |

| 5. Contact Adhesive |

| 6. Elastic adhesive |

| 7. EPDM tape |

| 8. Fiberglass tape |

| 9. Spackling compound |

| 10. Finishing paint |

QUALITY OF ASSEMBLY. HOW DO WE DO IT?

1. We adhere solid rubber to the wall using a hybrid elastic adhesive. This allows for maneuvering the pre-attached panel to precisely align the elements with each other, as well as with the ceiling and adjacent walls.

2. We adhere a rebound polyurethane foam using contact adhesive, which is sprayed on both surfaces to be bonded. Any gaps between the panels are filled with a technical sealant to eliminate potential acoustic bridges.

3. We apply acoustic plasterboard using contact adhesive, which is sprayed onto both surfaces being joined.

4. We reinforce the joints of plasterboard with glass fiber tape and apply elastic filler such as Siniat Nida Multitask compound.

5. We make the joints between plasterboard panels and adjacent walls or ceilings using the “controlled crack” technique to reduce the risk of cracking. The finish is completed with acrylic.

6. We perform initial and final sanding of the dried compound using dust extraction tools. This reduces dust generation during surface preparation.

PRICE:

System prime: 600 zł/m2

Included in the price:

Not included in the price:

Please contact us: based on photos and dimensions, we will prepare an accurate estimate for the project.